Before you make an investment in a cement silo, you may be wondering if and how it will benefit your business. Adding a cement silo to your business operations can be an advantage. This type of silo is able to store larger amounts of bulk cement, and this makes accessibility much easier.

However, the primary consideration is to make sure that the cement silo has a minimum capacity of at least one full tanker. That is equaled to 25 to 27 tons per load. One cubic foot of cement, also known as a bag, weighs around 94 pounds. It takes four bags to equal one barrel.

So, what are some ways that investing in a cement silo will help you save more money?

Employee Productivity Improvement

The majority of the time, a cement silo will pay for itself within two years. You will be saving money by changing the way you purchase cement. Instead of purchasing cement by the bag, you will be able to purchase it in bulk. As a result, the process to break even in your investment speeds up.

Other examples of savings includes:

– Saving time collecting and disposing of empty bags

– Requiring less storage space for pallets that contain bagged cement

– Reduced transportation costs to take cement to mixer

With the savings, you can use the extra money to increase employee wages or to streamline another area of your business.

Improved Safety/Safer Working Environment

When using bagged cement, employees must be in close proximity of the product in order to accurate measure and mix the wet and dry materials. The airborne particles that are released when the cement bags are opened are dangerous to humans if they are inhaled.

By investing in a cement silo for sale, you will have a cleaner and safer working environment for your employees. The transfer auger allows the cement to go to the point where it is ready to be released. This way exposure to cement dust is drastically reduced.

What Are The Most Common Configurations For Cement Silos?

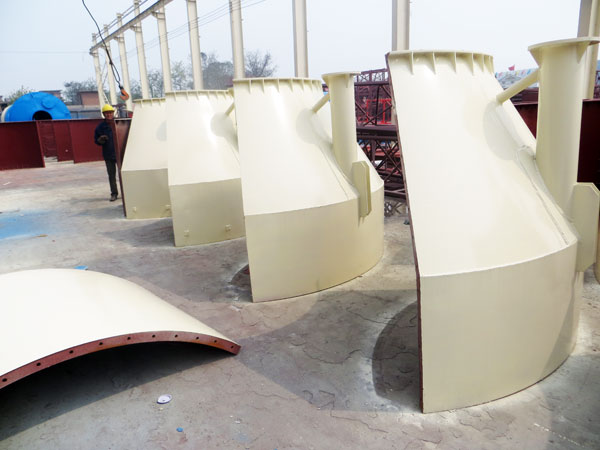

Cement silos for sale are built in two shapes. One shape is the rectangular shape and the other is the round upright shape. The rectangular shape has a lower profile, while the upright shape has a vertical range between 25 and 35 feet. Because of its width, the upright silo can hold 40 to 60 tons of cement.

The benefits of using a round upright cement silo instead of a rectangular one is that the upright silo has greater holding capacity. It also has a baghouse that is mounted on top of it.

A baghouse is a part of a silo that is used to filter the cement. This means that the cement can stay in the silo while the air is able to exit through the baghouse.

The rectangular, low profile cement silo is typically used where there are mobility or height restrictions. These types of silos have a holding capacity that ranges between 30 to 32 tons.

Regardless of the type of bolted silo you choose, these types of silos need to be inspected at least once a year. Most manufacturers recommend inspecting silos during the spring because they can sit unused during the colder months. Snow, ice and moisture can affect the structure. Any issues with the silo will be evident once warmer weather arrives.